All Over Screen Printing

Eco Stich has covered you here, too, with its special All-over screen-printing services. Being in the business for more than 02 decades has enabled us to master every kind of printing method used to transfer the design to the fabric.

We have got you covered for every of your brand personalization needs and customization you are looking for. Putting your logo on the edge of one sleeve often results in irregular positioning of your logo and brand design if not done correctly.

From Design to Fabric, We are Expert Printing Covering All Areas for You

We are pretty handy in working with every kind of simple, decent, creative and complex design idea you have in your mind. We specialize in the art of placing the unique logo, style, and pattern on your hoodie pocket and making your brand collection exclusive from your competition.

Assuring the use of the best custom screen-printing standards, we regularly change inks, use the latest and advanced machines and package your custom order in a way that looks finest. Eco Stich will find a reasonable solution for you.

Eco Stich provides multiple options for printing, which include silk screen printing, all-over sublimation printing, heat transfer printing, digital printing, and even direct-to-garment printing.

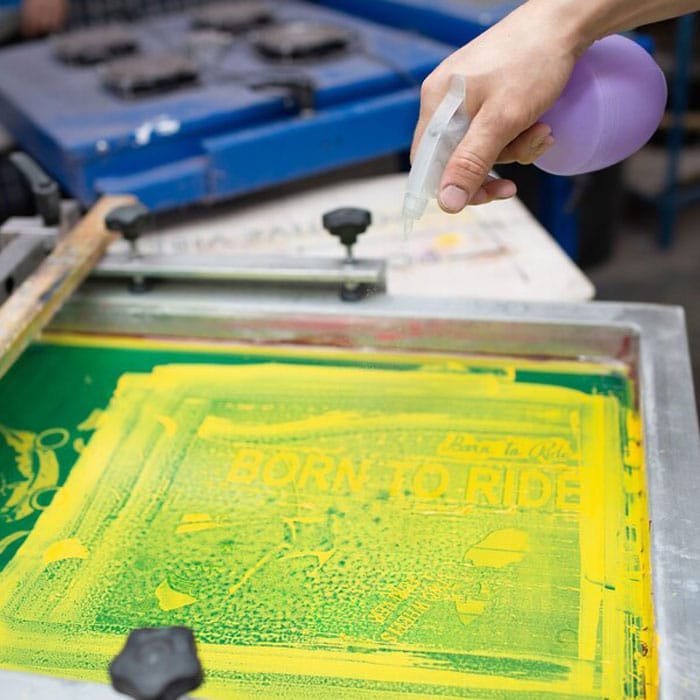

Silk Screen Printing

Silkscreen printing is a popular and easy method for printing designs on products like T-shirts, jackets, hoodies, and more. It is fabric-friendly and can print solid-color designs on almost any fabric, regardless of blend or processing. Eco Stich uses the best screen-printing techniques for complex designs, ensuring sharper and more precise results compared to butter paper. Our process allows for complex designs utilization of modern machines.

Flock Screen Printing

The flock screen printing method, also known as flocking, is a printing approach which includes the addition of dye, tiny fibre particles, and adhesive over the fabric of a t-shirt or printing product. Flock screen printing results in a tremendous velvety, silky look that feels soft and fluffy to the touch. Adding a flocky touch to your custom screen-printed design makes the design stand out from others and engages your customers quickly.

Water Based/Pigment Screen Printing

As the name tells, Pigment screen printing/ water-based screen printing uses water as the primary solvent for carrying the pigment. The process is similar to discharge screen printing, but the difference is its pigment (color) is based on water instead of plastic-based liquid or Plastisol. This screen-printing method is primarily used on white and light color garments. It is best suited on light-color fabric such as white, off-white, light grey, etc.

Discharge Screen Printing

Discharge printing is another popular screen-printing method used in the fashion industry. The technique works on the bleaching principle, where the discharge ink is used to remove the dyed areas, resulting in a new color formation over the fabric.

The inks are transferred to shirts. They remove the original color from any spot and replace it with the applied color. In terms of feel, the fabric feels soft, comfortable and durable look.

High Density 3D

Eco Stich, also known as sustainable 3D printing, employs specialized ink to emboss intricate 3D patterns onto fabric, enhancing the visual and tactile appeal of apparel items. Distinguished by its crisp detailing, Eco Stich sets itself apart from traditional methods like puff printing. Utilizing thick, high-viscosity ink, Eco Stich deposits multiple layers onto the fabric surface, creating a textured, dimensional effect that elevates various apparel products, adding a unique eco-friendly touch.

Crack Screen Printing

Known alternatively as shatter screen printing, crack screen printing is a prominent and versatile technique within the fashion realm. Its accessibility to diverse design innovations makes it a favored choice among creators. In crack screen printing, specialized crack ink is applied, setting and drying to produce distinctive ridges and a groovy aesthetic. The fractured appearance offers a captivating glimpse into a unique fracture pattern, enhancing the visual allure of the printed garment.

Puff Screen Printing

Glow In Dark Printing

Dye Sublimation Process

Sticker Heat Transfer Printing

Digital Printing

Direct to Garment (DTG)

Get In Touch

Phasellus ultricies ex vitae neque placerat porta. Aenean libero eros ultrices vel tristique non, porta eget dolor. Donec vel ipsum imperdietum.

Phone

+123-234-1234

info@ecostich.com